How a Fume Hood Works

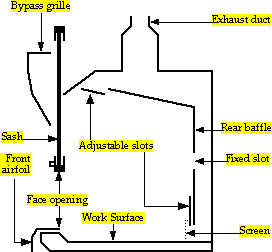

A fume hood is a ventilated enclosure in which gases, vapors and fumes are contained. An exhaust fan situated on the top of the laboratory building pulls air and airborne contaminants through connected ductwork and exhausts them to the atmosphere.

The typical fume hood found in Southern Utah University laboratories is equipped with a movable front sash and an interior baffle. Depending on its design, the sash may move vertically, horizontally or a combination of the two and provides some protection to the hood user by acting as a barrier between the worker and the experiment.

The slots and baffles direct the air being exhausted. In many hoods, they may be adjusted to allow the most even flow. It is important that the baffles are not closed or blocked since this blocks the exhaust path.

The airfoil or beveled frame around the hood face allows more even airflow into the hood by avoiding sharp curves that can create turbulence.

There are basically two types of fume hoods at SUU, they are:

Constant Volume - where the exhaust flowrate or quantity of air pulled through the hood is constant. Therefore, when the sash is lowered and the cross-sectional area of the hood opening decreases, the velocity of airflow (face velocity) through the hood increases proportionally. Thus, higher face velocities can be obtained by lowering the sash.

Variable Air Volume (VAV) - where the exhaust flowrate or quantity of air pulled through the hood varies as the sash is adjusted in order to maintain a set face velocity. Therefore, when the sash is lowered and the cross-sectional area of the hood opening decreases, the velocity of airflow (face velocity) through the hood stays the same while less total air volume is exhausted.