Fume Hood Proper Work Practices

The level of protection provided by a fume hood is affected by the manner in which the fume hood is used. No fume hood, however well designed, can provide adequate containment unless good laboratory practices are used, as follow:

- The hood user should know the normal operating configuration (NOC) of the hood and should design experiments so that this configuration can be maintained whenever hazardous materials might be released. The NOC refers to the position of the sash that was established when the hood was installed and certified (i.e. how far open is the maximum safe sash position).

- Before using the hood, the user should check the hood survey sticker to determine where the sash should be positioned for optimum containment for that particular unit.

- The hood user should also check the magnehelic gauge or other hood performance indicator and compare its reading to the reading indicated on the hood survey sticker. If the reading differs significantly (20% or more for a magnehelic gauge) from that on the sticker the hood may not be operating properly. Contact Facilities Management with hood location and contact information.

- Never use a hood to control exposure to hazardous substances without first verifying that it is operating properly.

To optimize the performance of the fume hood, follow the practices listed below:

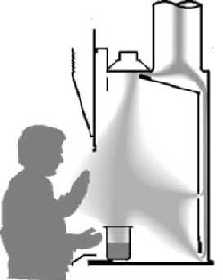

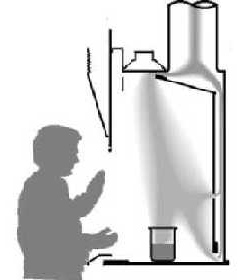

Mark a line with tape 6 inches behind the sash and keep all chemicals and equipment behind that line during experiments. This will help to keep materials from escaping the hood when disturbances like air currents from people walking past the hood, etc., interfere with airflow at the face of the hood.

|

|

|

| Poor placement of materials | Good placement of materials | Best placement of materials |

Images from Kewaunee Fume Hoods

Keep the sash completely lowered any time an experiment is in progress and the hood is unattended. Note: Lowering the sash not only provides additional personal protection, but it can also result in significant energy conservation. Keep the hood sash clean and clear.

Check area around the hood for sources of cross drafts, such as open windows, supply air grilles, fans and doors. Cross drafts may cause turbulence that can allow leaks from the hood into the lab.

Extend only hands and arms into the hood and avoid leaning against it. If the hood user stands up against the face of the hood, air currents produced by turbulent airflow may transport contaminants into the experimenter's breathing zone.

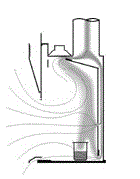

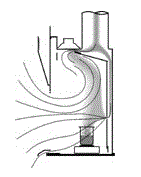

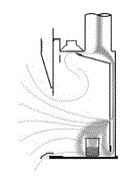

Visually inspect the baffles (openings at the top and rear of the hood) to be sure that the slots are open and unobstructed. For optimum performance, adjust the baffles when working with high temperature equipment and/or heavy gases or vapors. See figure below for suggested baffle positions.

|

|

|

| Normal baffle positioning |

Baffle position to use for hot work |

Baffle position for heavy gases |

Normal baffle position all slots are evenly opened.

High temperature work such as using hot plates; lower slots are minimized since heated vapors tend to rise.

Heavy gasses and vapors are better captured when upper slots are minimized.

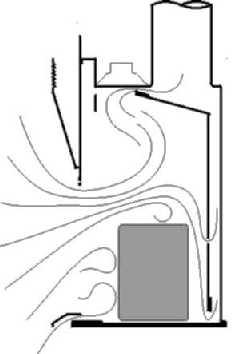

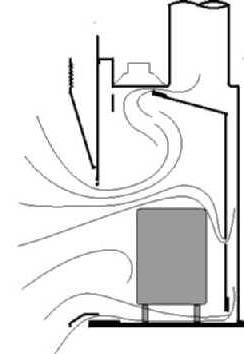

Do not block slots. If large equipment must be placed in the hood, put it on blocks to raise it approximately 2 inches above the surface so that air may pass beneath it. See figure below.

|

|

| Poor large equipment placement | Good large equipment placement |

Place large or bulky equipment near the rear of the fume hood. Large items near the face of the hood may cause excessive air turbulence and variations in face velocity.

Do not use the hood as a storage device. Keep only the materials necessary for the experiment inside of the hood. If chemicals must be stored in the hood for a period of time, install shelves on the sides of the hood, away from the baffles.

Provide secondary containment for containers that could break or spill, to minimize the spread of spilled liquids.

Items contaminated with odorous or hazardous materials should be removed from the hood only after decontamination or if placed in a closed outer container to avoid releasing contaminants into the laboratory air.

When using cylinders containing highly toxic or extremely odorous gases, obtain only the minimal practical quantity. Consider using a flow-restricting orifice to limit the rate of release in the event of equipment failure. In some circumstances, exhaust system control devices or emission monitoring in the exhaust stack may be appropriate.

All electrical devices should be connected outside the hood to avoid electrical arcing that can ignite a flammable or reactive chemical.

DO NOT USE A HOOD FOR ANY FUNCTION FOR WHICH IT WAS NOT INTENDED. Certain chemicals or reactions require specially constructed hoods. Examples are perchloric acid or high pressure reactions. Most special use hoods are labeled with the uses for which they are designed.